Echo Acoustic Liquid Handlers

Echo Acoustic Liquid Handlers (or Dispensers) are advanced lab automation instruments that use sound waves to transfer liquid droplets as small as 2.5 nanoliters from any source well to any destination well—without physical contact or pipette tips.

Originally developed by Labcyte, Echo Acoustic Liquid Handlers are now a key component of our automated liquid handling portfolio. Powered by Acoustic Droplet Ejection (ADE) technology, they are transforming how scientists perform high-throughput experiments across a wide range of applications, including drug discovery, sample management, synthetic biology, genomics, proteomics, and functional screening workflows.

Echo Acoustic Liquid Handler Benefits

- Echo Acoustic Liquid Handlers deliver highly precise (<8% CV) and accurate (<10% deviation from target volume) liquid dispenses even in the nanoliter range

- Ability to create direct dilutions significantly increases data quality because the risk of error propagation, problematic for serial dilutions, is eliminated

Since the Echo Acoustic Liquid Handlers use sound waves to move liquid, there's no physical contact—meaning no tips and lower risk of cross-contamination and carryover when compared to the traditional tip-based pipetting.

- Quick transfer of liquids up to 700 drops per second

- The acoustic transducer and destination plate are moved simultaneously, enabling transfers from any source well to any destination well.

- No delays due to tip changes between transfers.

Miniaturization of assays leads to a significant reduction in their cost, for example:

- 91% compound and 8000 L/year DMSO savings with a fully Acoustic Assay-Ready Plate (ARP) workflow1

- Hundreds of kg down to ~7 mg of building blocks and ~20 mgs of solvent to acoustically synthesize 1536 novel compounds2

1 Green CP, Spencer PA, Sarda S. Drug Discov Today. 2021. 26(1):5–9. doi: 10.1016/j.drudis.2020.09.032.

2 Gao L et al. Green Chem. 2023. 25(4):1380-1394. doi: 10.1039/d2gc04312b.

- Dynamic Fluid Analysis (DFA) technology automatically adjusts transfer parameters based on fluid properties in real time, ensuring consistent performance across diverse sample types

- Complex combinatorial transfers, multi-source pooling, and high-throughput screening

- Wide range of applications

- Integratability with Access systems and other instruments

Echo Acoustic Liquid Handlers:

- Customers have been able to decrease in overall plastic usage by 87% and simultaneously save 72% in NGS prep and sequencing costs3

- Support transfers from reusable acoustic sample tubes and microplates without tips, cutting down on plastic waste. For example, over 35 million tips saved annually by IDT deploying Acoustic Liquid Handling4

3 Torkamaneh D et al. Front Genet. 2020. 11:67. doi: 10.3389/fgene.2020.00067.

4 http://www.linkedin.com/pulse/reducing-plastic-pollution-one-tip-time-tom-speedy-jpvpe

Echo Acoustic Liquid Handler Models

*Enables relative humidity (RH) and temperature control when integrated with enclosed automation solutions such as an Access SRS/DRS System. Requires customer-supplied HVAC supply. Temperature and RH must conform to instrument specifications.

**650T, 655T and enabled models

Echo-based Custom Lab Automation

We understand that most of your lab tasks go far beyond simply transferring liquid from one well to another. That’s why we offer everything you need to transform your standalone Echo Acoustic Liquid Handlers into a fully integrated, walkaway system—perfectly tailored to your sophisticated workflows:

- Access Solutions Group – a team of professionals who have delivered thousands of custom lab automation solutions

- 30+ years of expertise automating liquid handling and robotic systems with more than 400 device drivers from more than 77 suppliers

- More than 233 device drivers which we actively maintain so they are ready to use

- Software tools developed for automation scheduling, data management and lab orchestration

- Seamless integration of your Echo Applications Protocols into our scheduling software so you do not need to rewrite your applications

Frequently Asked Questions

This is a tip-less and contact-free type of liquid handling that uses sound energy to transfer liquids in nanoliter-scale increments. This technology enables transfers from any source well to any assay well(s) - all without making physical contact with your sample. Visit this page to explore the details about Acoustic Droplet Ejection technology behind the Echo instruments.

Echo Acoustic Liquid Handlers don't require end user calibration - they are ready for transfers following installation. Technologies such as Dynamic Fluid Analysis allow the instrument to adapt easily to changing fluid properties such as the hydration state of DMSO as well as varying volumes in the source well.

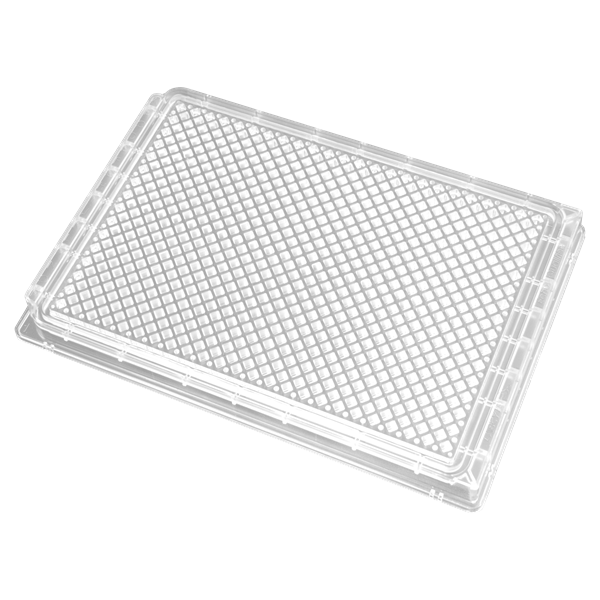

Echo Qualified Microplates and Reservoirs are required source labware. For destination labware e.g. the assay plate, most skirted plates (<16mm) conforming to ANSI/SLAS 1-2004 are compatible. Labware such as microfluidic chips or slides can also be used as destination labware when used with appropriate adapters.

Absolutely! One benefit of our TEMPO and SAMI EX scheduling software is the ability to directly use the Echo Apps protocols from your standalone development in the larger robotic lab automation scheduler. This helps ensure you get a similar experience and results to running the standalone Echo Liquid Handler, without having to re-write all your dispensing methods.

No! The Acoustic Droplet Ejection technology uses sound waves to form mounds of fluid and subsequent nanoliter-scale ejections inside the well to be transferred. It is very gentle: our pharma, biotech, and biofoundry customers frequently transfer nucleic acids, and biologics such as antibodies. Even sensitive cells such as iPS cells (iPSCs) have been successfully transferred with the technology.5

5 Gérard A at al. Nat Biotechnol. 2020. 38(6):715-721. doi: 10.1038/s41587-020-0466-7

To answer this question, we need to learn more about your workflows to choose the best suitable solution. Please fill out this form to start the conversation.

Echo instruments were initially developed and manufactured by Labcyte Inc. In 2019, Labcyte became a Beckman Coulter company.

It's officially an Echo Acoustic Liquid Handler but they've been referred to as Acoustic Dispensers, Acoustic Pipettors... Acoustic Amazingness Facilitators. That last one's a little strange but points to the transformative nature of our technology.

Didn't find an answer to your question? Talk to our expert.

Used Together With

Explore Applications

These products are not intended or validated for use in the diagnosis of disease or other conditions.

ECHO is a trademark or registered trademark of Labcyte Inc. in the United States and other countries. Labcyte is a Beckman Coulter company. All other trademarks are the property of their respective owners.